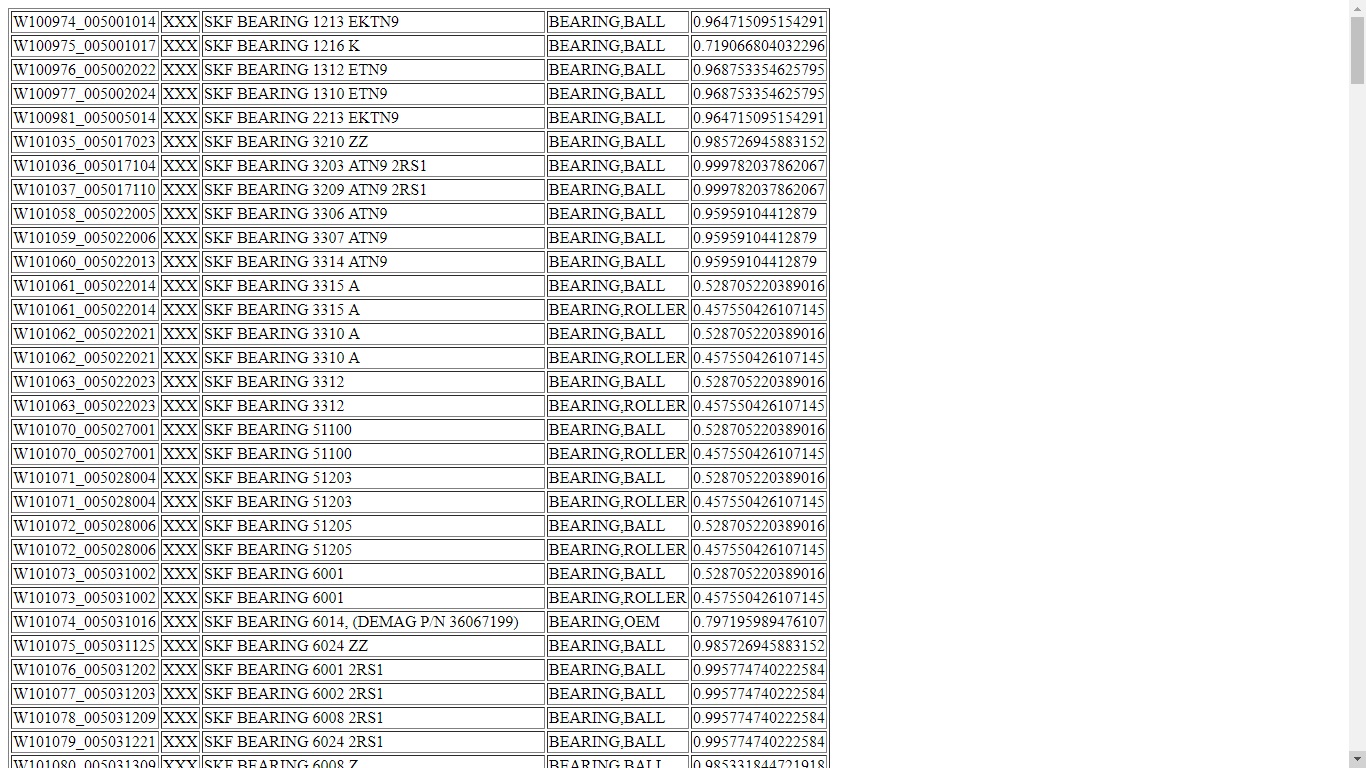

- Data Analysis

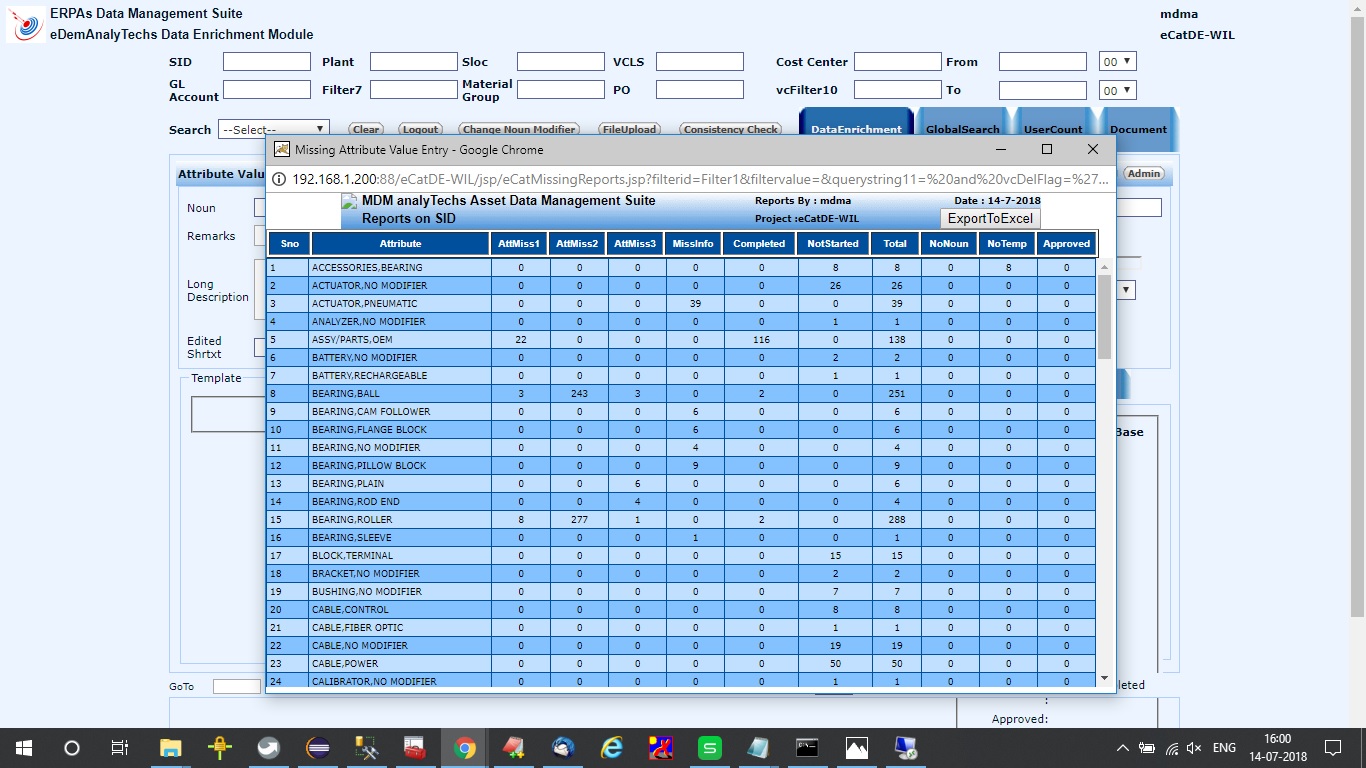

A pre engagement data analysis of done is carried out by our experts to determine the structure, consistency and Quality of available data and understand the pain areas for the customer.

Outcome of Data Analysis, determines Goals, objectives, engagement model, data structure, deliverable, time frames and quality requirements.

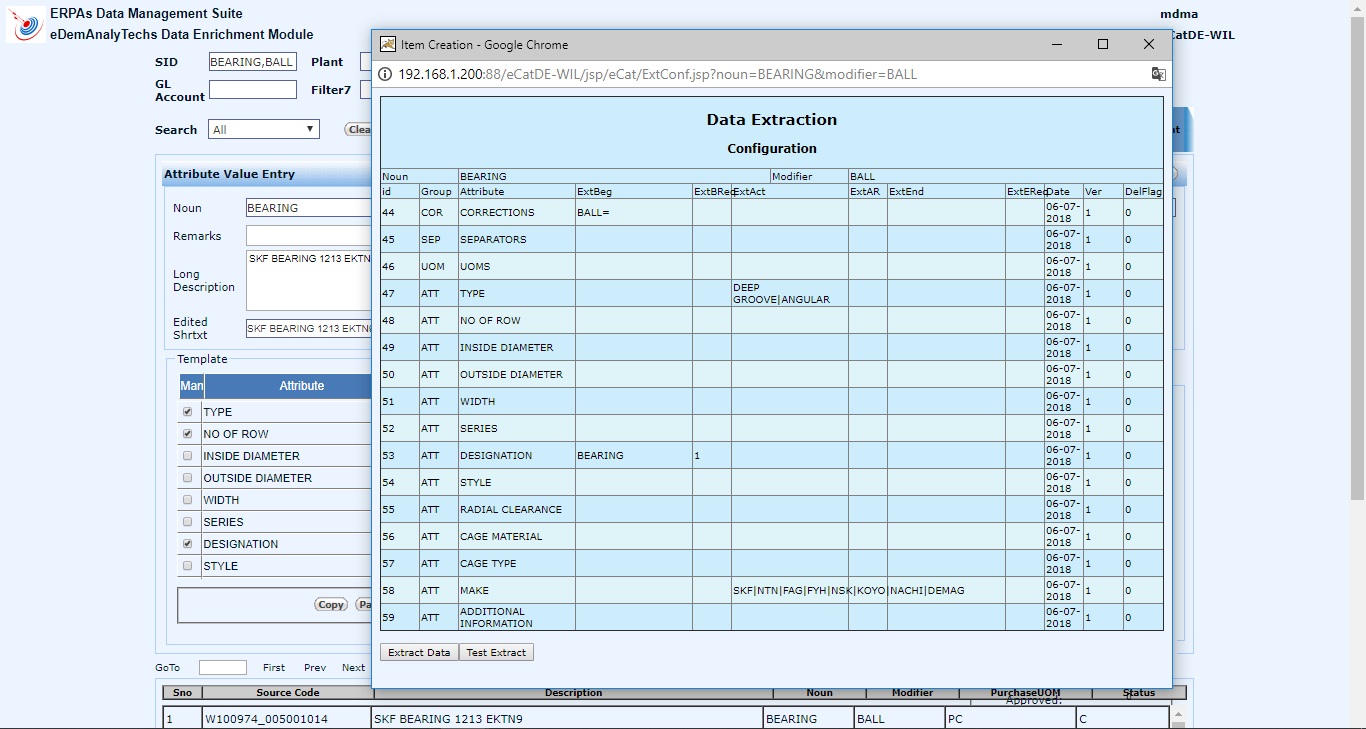

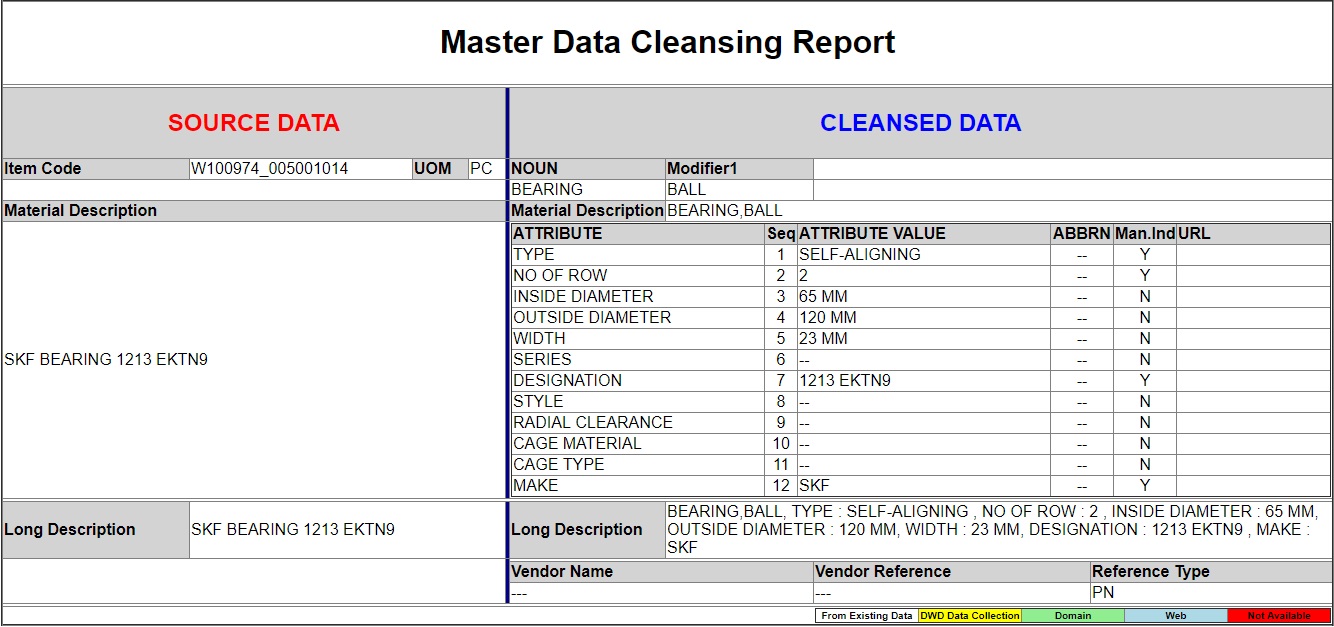

- Data Cleansing

ERP AnalyTechs provides services towards

- Assignment of correct classification.

- Data normalization and rationalization

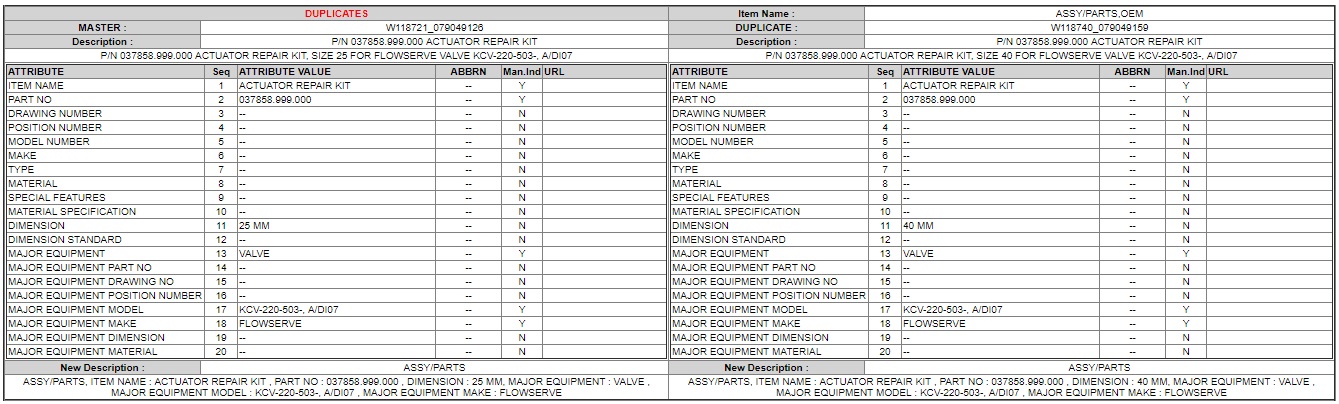

- Duplicate identification and removal

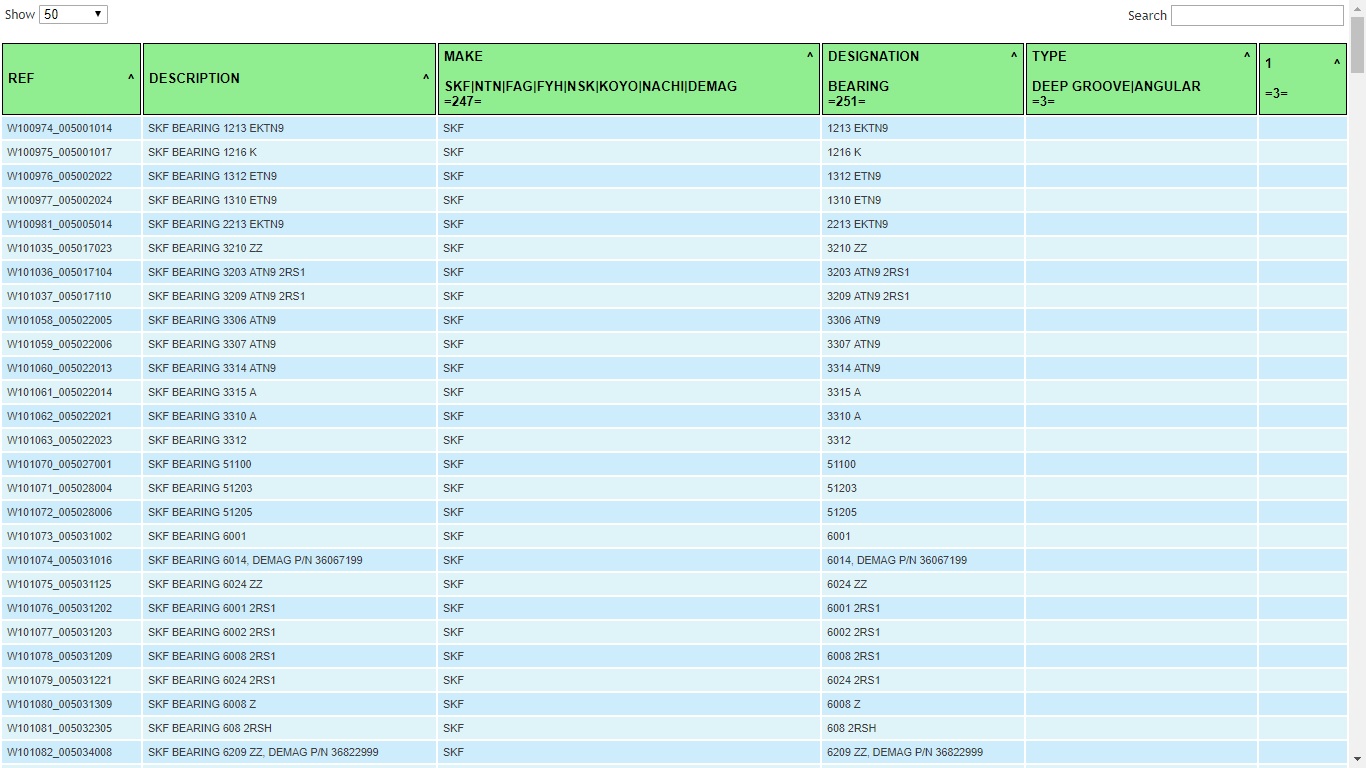

- Attribute extraction and population with agreed taxonomies, that are complaint to standards or owned by customers using In house developed Pattern matching, automated, AI Software tool SENSEROID, standard dictionaries and data repository available with them.

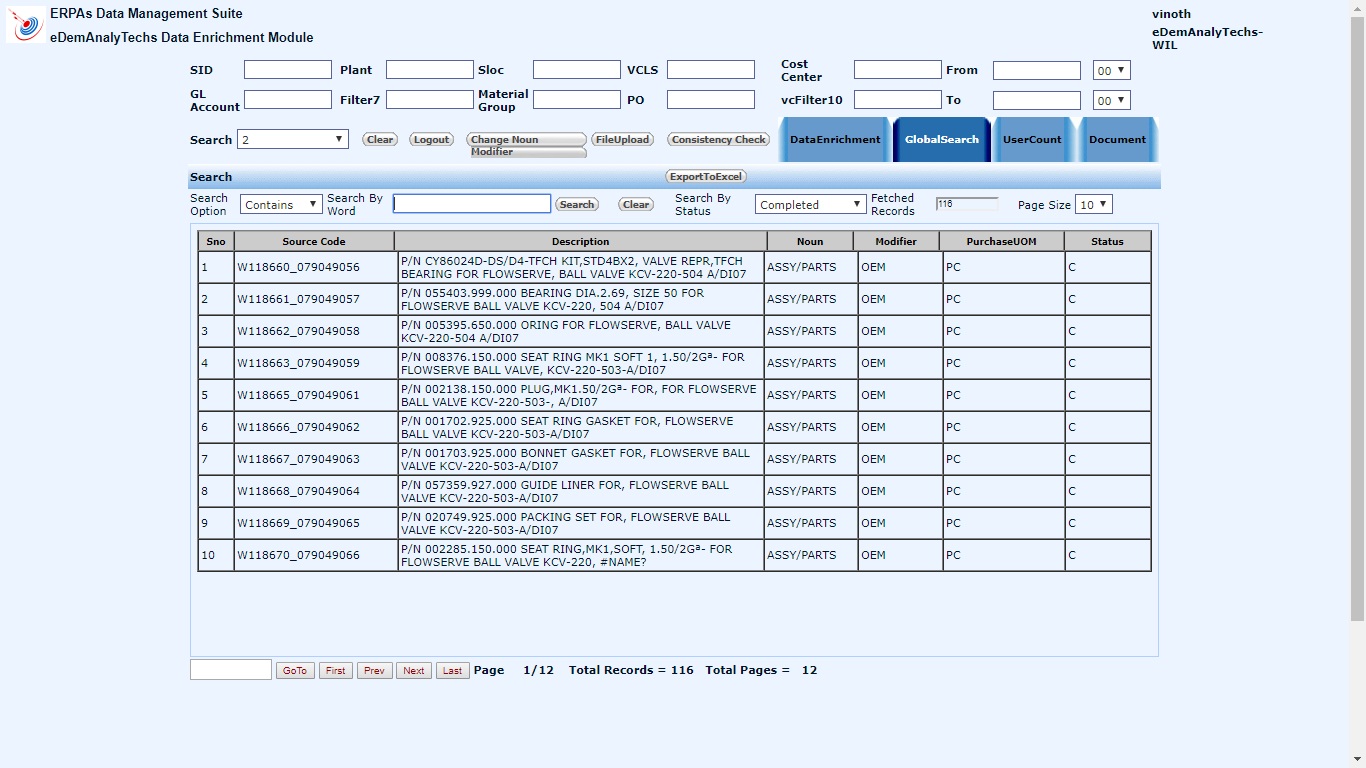

- Data Enrichment, enhancement and duplicate identification.

ERP AnalyTechs provides services towards

Abbreviation Expansion

Data enrichment by sourcing manufacturer websites

Data enrichment by “manual sourcing” i.e. by contacting suppliers for additional data

Data enrichment by collecting additional data by “Physical data collection” and interaction with users

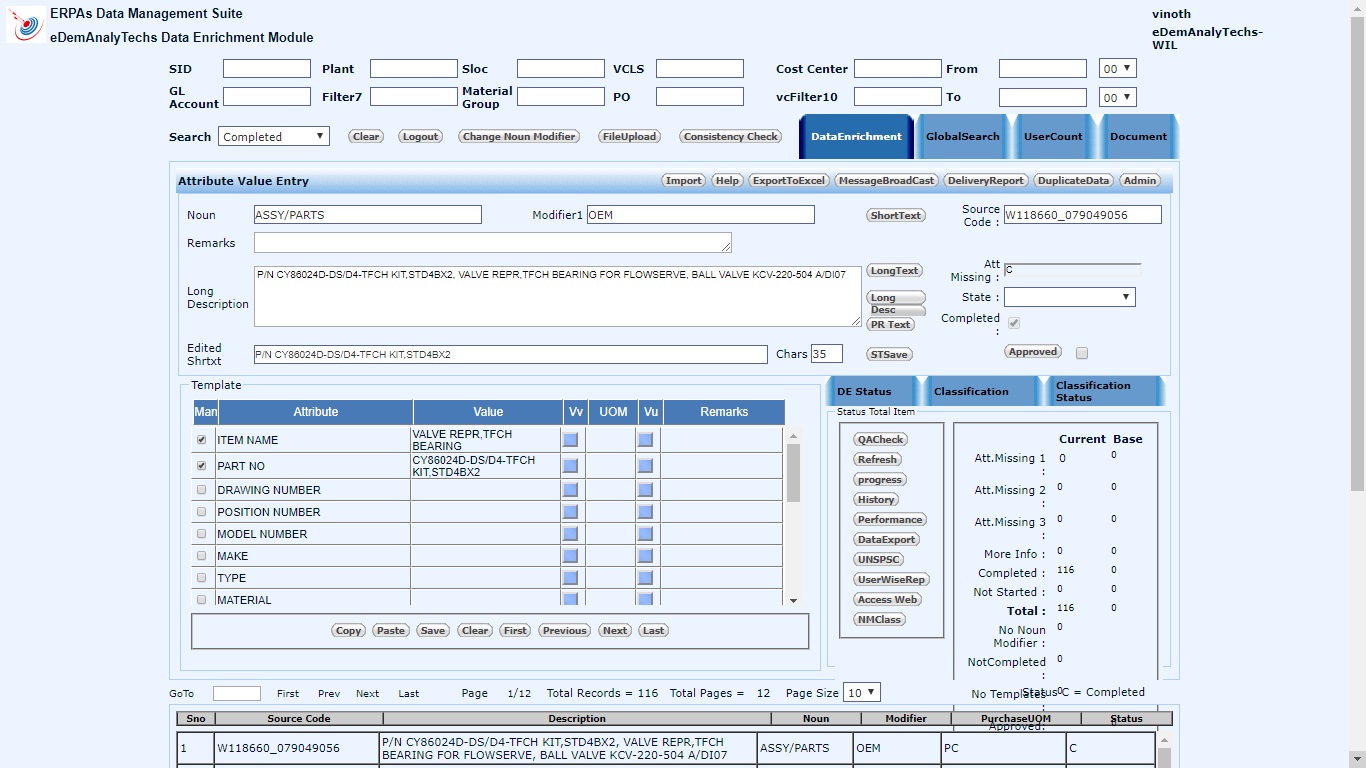

These services are enabled by in house developed Data Enrichment Tool, eDemAnalyTechs.

ERP AnalyTechs provides this service as a logical extension to Data cleansing and Enrichment activities, Using in house developed tool eDemAnalyTechs to Standardize Data Structure, Descriptions, Abbreviations, UoM’s, Terminologies, definitions and guidelines.

Data preparation work for Maintenance module to ensure Equipment and related data are ready for use with due linkages. The services include

Preparation of functional hierarchies- A diagram that clearly explains the functions of a system in a hierarchical fashion. This include Company, plant, area, location, system, sub system, tag, equipment, in a hierarchical fashion throughout the facility for all systems based on agreed rules and requirement of the business.

Criticality analysis- Criticality of the system / equipment based on the function performed.

Equipment Register- Specifications of the system/ equipment with quantities.

Bill of Materials- List of assemblies, sub assemblies, sub sub assemblies and components, with specifications and quantities for equipment and due linkage to higher level equipment.

Job Plans for Plant assets and equipment- Preparation of various maintenance tasks, frequency of task, tools, spare parts, human resources requirements for every equipment.